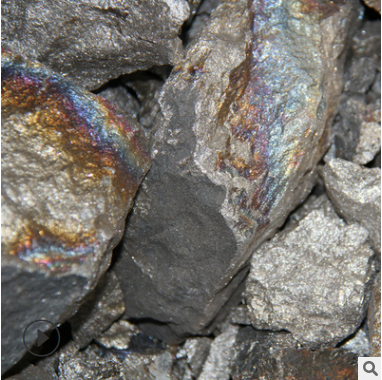

Ferrosilicon is made of iron silicon alloy made of coke, steel chips, quartz (or silica) as raw material and smelted by electric furnace. Because silicon and oxygen are easy to combine into silicon dioxide, so ferro silicon is often used as deoxidizer in steelmaking. At the same time, due to the release of a lot of heat when SiO2 is generated, it is beneficial to improve the temperature of molten steel at the same time of deoxidation. Ferrosilicon should be widely used as an alloying element additive, widely used in low alloy structural steel, spring steel, bearing steel, heat resistant steel and electrical silicon steel, while ferrosilicon in ferroalloy production and chemical industry, but also commonly used as a reducing agent. Ferrosilicon is widely used in steelmaking, casting and ferroalloy industries. Among them, used as deoxidizer and alloy agent in steelmaking industry, used as inoculating agent and spheroidizing agent in cast iron industry, used as reducing agent in ferroalloy production. In a variety of different grades of ferrosilicon, ferrosilicon 75# is the most widely used, which is fESI75-B ferrosilicon futures contract corresponding to the benchmark delivery.

Part of ferrosilicon produced in China is exported overseas, mainly to neighboring countries such as Japan and Korea. Because ferrosilicon production is a high energy consumption industry, the country does not encourage exports and imposes tariffs on exports, which makes the proportion of ferrosilicon exports in China's output relatively stable in recent years, and has been maintained at about 5.5%. However, in 2017, the export tariff of ferrosilicon was lowered from 25% to 20%, which stimulated the export to a certain extent. The proportion of ferrosilicon export increased significantly, rising to 9.24% that year.